Long-Term Bulge Repairs for Coke Drums

When bulging severity reaches unacceptably high levels, long-term repairs become necessary. Several approaches have been used to implement bulge repairs over the year such as window replacement, can replacement, and weld overlay. Each technique has its advantages and disadvantages. The best repair method for a particular drum depends on the extent of damage, expected remaining service life, age, maintenance history, and drum design. Poorly-designed repairs can move the problem elsewhere or make a bad situation worse.

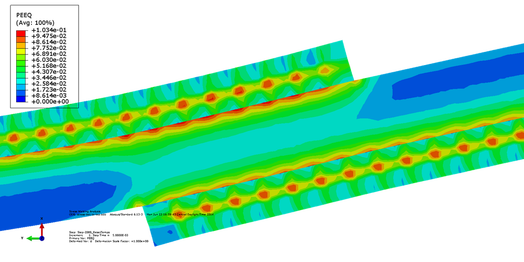

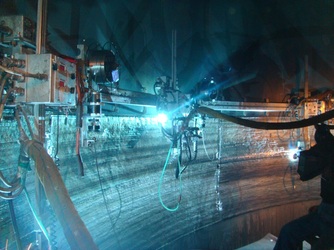

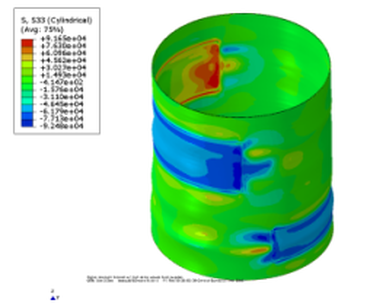

After the type of repair is determined, the more difficult task is determining repair details. These details are particularly important for the widely-used automated weld overlay technique which is often the most effective solution. If a weld overlay repair is pursued, the application surface, overlay thickness, weld material, and perimeter treatment are all critical details that dictate the success of the solution. Improperly designed repairs can lead to excessive distortions and/or local buckling. Also, if an overlay is applied on the wrong side of the wall, faster crack propagation and accelerated bulging can occur at nearby locations. Simulation of repairs using the finite element method is used to verify that the benefits of the repair are realized without suffering unintended negative consequences.

HES staff have developed numerous bulge repair plans for clients around the world including the largest in industry history. Please see articles in the Resources section of this website for more information.

After the type of repair is determined, the more difficult task is determining repair details. These details are particularly important for the widely-used automated weld overlay technique which is often the most effective solution. If a weld overlay repair is pursued, the application surface, overlay thickness, weld material, and perimeter treatment are all critical details that dictate the success of the solution. Improperly designed repairs can lead to excessive distortions and/or local buckling. Also, if an overlay is applied on the wrong side of the wall, faster crack propagation and accelerated bulging can occur at nearby locations. Simulation of repairs using the finite element method is used to verify that the benefits of the repair are realized without suffering unintended negative consequences.

HES staff have developed numerous bulge repair plans for clients around the world including the largest in industry history. Please see articles in the Resources section of this website for more information.