News and Announcements

Ameriscan merges into HES

Sep. 20, 2023 - Specialty testing company Ameriscan LLC merges into sister company Houston Engineering Solutions, LLC. Ameriscan which was founded in 2018 specializes in acoustic emission testing and laser scanning of coke drums. The merger streamlines operations and allows HES to offer a complete set of engineering and testing services under one roof.

Sep. 20, 2023 - Specialty testing company Ameriscan LLC merges into sister company Houston Engineering Solutions, LLC. Ameriscan which was founded in 2018 specializes in acoustic emission testing and laser scanning of coke drums. The merger streamlines operations and allows HES to offer a complete set of engineering and testing services under one roof.

HES Receives Patent on Coke Drum Bottom De-Heading Device with Inlet

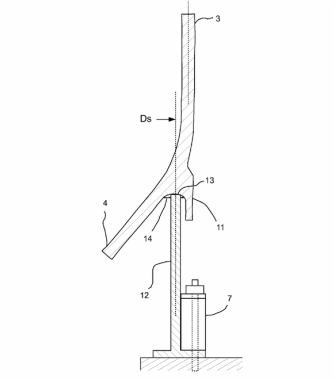

Feb. 9, 2021 - Houston Engineering Solutions, LLC was issued a US patent for a novel coke drum de-heading device with an integral feed nozzle. The device combines the safety of automated unheading with robust operation from a symmetric fluid flow.

Feb. 9, 2021 - Houston Engineering Solutions, LLC was issued a US patent for a novel coke drum de-heading device with an integral feed nozzle. The device combines the safety of automated unheading with robust operation from a symmetric fluid flow.

HES Signs Agreement with Sumitomo

Oct. 20, 2020 - Houston Engineering Solutions, LLC of Houston, TX signed an agreement with Sumitomo Heavy Industries of Japan that provides the latter a license to fabricate HES' patented bulge-resistant coke drum design. The agreement sets the stage for utilizing the new design that is intended to reduce the likelihood of developing the classic seam bulging observed in these large refinery vessels.

Oct. 20, 2020 - Houston Engineering Solutions, LLC of Houston, TX signed an agreement with Sumitomo Heavy Industries of Japan that provides the latter a license to fabricate HES' patented bulge-resistant coke drum design. The agreement sets the stage for utilizing the new design that is intended to reduce the likelihood of developing the classic seam bulging observed in these large refinery vessels.

Bulge-Resistant Coke Drum Patent Issued

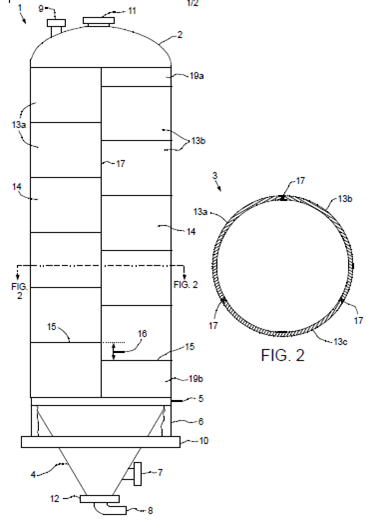

Feb. 6, 2018 - HOUSTON ENGINEERING SOLUTIONS, LLC was granted US Patent 9,884,996 B2 for Bulge-Resistant Coke Drum by the US Patent Office. A coke drum apparatus including: a cylindrical section; a cap connected to an upper end of the cylindrical section; a bottom, and a knuckle connecting the bottom and the cylindrical section. The cylindrical section includes a plurality of arcuate segments attached together by vertical welds. Each arcuate segment includes a plurality of arcuate plates attached together by circumferential welds. The circumferential welds of each arcuate segment are offset from the circumferential welds of each adjacent arcuate segment. The patented design is intended to reduce the likelihood of developing the classic seam bulging observed in these large refinery vessels.

Feb. 6, 2018 - HOUSTON ENGINEERING SOLUTIONS, LLC was granted US Patent 9,884,996 B2 for Bulge-Resistant Coke Drum by the US Patent Office. A coke drum apparatus including: a cylindrical section; a cap connected to an upper end of the cylindrical section; a bottom, and a knuckle connecting the bottom and the cylindrical section. The cylindrical section includes a plurality of arcuate segments attached together by vertical welds. Each arcuate segment includes a plurality of arcuate plates attached together by circumferential welds. The circumferential welds of each arcuate segment are offset from the circumferential welds of each adjacent arcuate segment. The patented design is intended to reduce the likelihood of developing the classic seam bulging observed in these large refinery vessels.

Three coke drum inventions unveiled

Houston Engineering Solutions, LLC of Houston, Texas unveiled three inventions that were recently developed to address the three most common failure modes in coke drums, namely skirt attachment cracks, shell bulging, and anchor bolt failures. A new skirt design, shell fabrication method, and drum anchoring system were introduced and discussed at the coking track of RefComm in Galveston on May 5, 2016. The three patented inventions can be utilized for designing new drums as well as for retrofitting existing ones. Currently, the new skirt and anchoring system are being implemented by operating companies in Saskatchewan and Alberta, respectively, to retrofit drums that have suffered recent failures. The announcement was made by Company president and inventor, Dr. Mahmod Samman.

Houston Engineering Solutions, LLC of Houston, Texas unveiled three inventions that were recently developed to address the three most common failure modes in coke drums, namely skirt attachment cracks, shell bulging, and anchor bolt failures. A new skirt design, shell fabrication method, and drum anchoring system were introduced and discussed at the coking track of RefComm in Galveston on May 5, 2016. The three patented inventions can be utilized for designing new drums as well as for retrofitting existing ones. Currently, the new skirt and anchoring system are being implemented by operating companies in Saskatchewan and Alberta, respectively, to retrofit drums that have suffered recent failures. The announcement was made by Company president and inventor, Dr. Mahmod Samman.