Fitness-For-Service

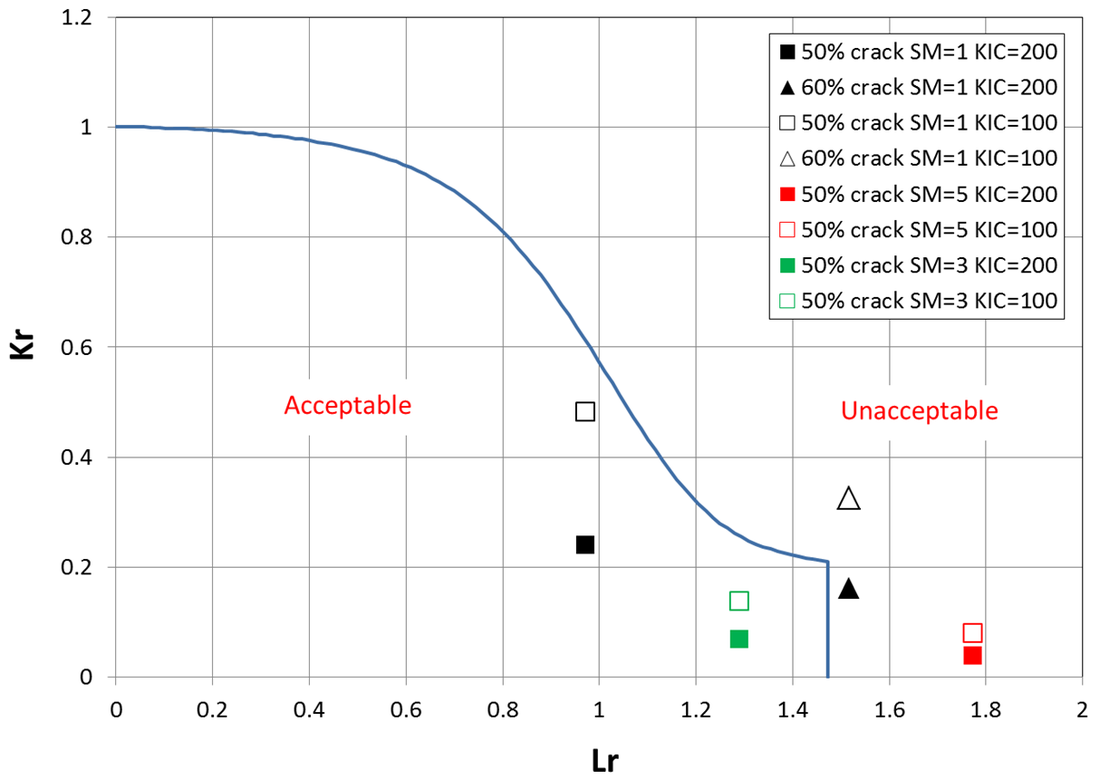

Fitness for Service is the ability to demonstrate the structural integrity of an in-service component containing a flaw. Practically, it can be defined as the process of determining if a structure with a known defect can be placed in service or not.

The need for such assessments comes from the fact that plant equipment and structures are usually exposed to loads, chemicals, and/or temperatures that cause the equipment to degrade with time. When defects such as cracks are discovered, plant engineers need to decide if they can continue operations in a safe, reliable, and economic manner. Incorrect decisions can lead to injuries, fatalities, property and environmental damage, unexpected shutdowns, and damage to company reputation.

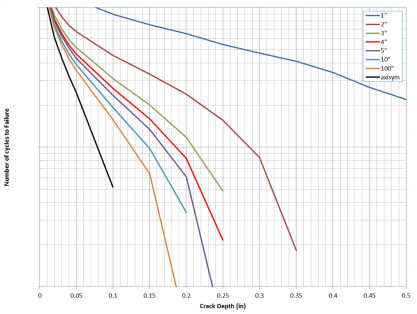

The process of conducting a fitness-for-service assessment is a multi-disciplinary engineering analysis that typically involves inspection, material, structural, and mechanical engineers. The analysis requires information on equipment operation history, maintenance history, nondestructive examination (NDE), and material properties. More complex assessments require finite element analysis. Industry standard API 579/ ASME FFS was developed utilizing industry experience to enhance safety and standardize the assessment process.

Fitness-for-service assessments are highly-specialized engineering analyses that require advanced technical skills, field experience, knowledge of applicable codes and standards, and powerful software. Houston Engineering Solutions has all these necessary components to conduct accurate assessments in a timely and cost-effective manner.

The need for such assessments comes from the fact that plant equipment and structures are usually exposed to loads, chemicals, and/or temperatures that cause the equipment to degrade with time. When defects such as cracks are discovered, plant engineers need to decide if they can continue operations in a safe, reliable, and economic manner. Incorrect decisions can lead to injuries, fatalities, property and environmental damage, unexpected shutdowns, and damage to company reputation.

The process of conducting a fitness-for-service assessment is a multi-disciplinary engineering analysis that typically involves inspection, material, structural, and mechanical engineers. The analysis requires information on equipment operation history, maintenance history, nondestructive examination (NDE), and material properties. More complex assessments require finite element analysis. Industry standard API 579/ ASME FFS was developed utilizing industry experience to enhance safety and standardize the assessment process.

Fitness-for-service assessments are highly-specialized engineering analyses that require advanced technical skills, field experience, knowledge of applicable codes and standards, and powerful software. Houston Engineering Solutions has all these necessary components to conduct accurate assessments in a timely and cost-effective manner.