Coke Drum Cracking Assessment

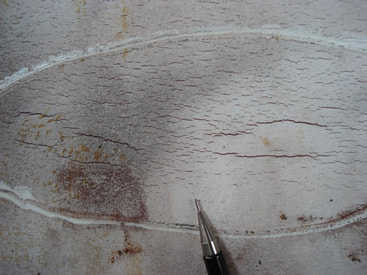

Industry standard API 579-1/ ASME FFS-1 contains elaborate rules for the assessment of cracks in pressure equipment. But, since coke drums are exposed to spatially and temporally-variable thermo-mechanical loads that cannot be accurately defined or predicted, a standard deterministic assessment of a coke drum crack located under the fill level cannot be performed with any accuracy. Even probabilistic crack assessment is not feasible because of the highly variable stress field.

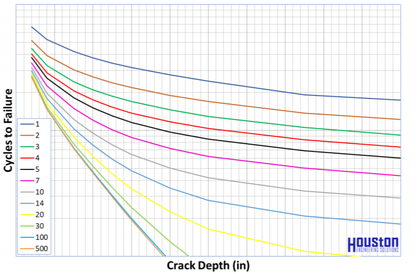

When refineries find numerous cracks during a turnaround and time is insufficient to repair them all, a decision needs to be made on which cracks are to prepared first. To meet this need, HES has developed a proprietary analysis process that uses fracture mechanics tools to prioritize repairs of observed cracks. The outcome of this process is a set of charts developed for each set of drums that calculate normalized cycles to failure for cracks in different plate thicknesses, locations (base plate/ weld), lengths, and depths. A software that automates the interpretation of these charts for expediting field decision making has also been developed. This process has been successfully used in demanding field conditions.

Please see articles in the Resources section of this website for more information.

When refineries find numerous cracks during a turnaround and time is insufficient to repair them all, a decision needs to be made on which cracks are to prepared first. To meet this need, HES has developed a proprietary analysis process that uses fracture mechanics tools to prioritize repairs of observed cracks. The outcome of this process is a set of charts developed for each set of drums that calculate normalized cycles to failure for cracks in different plate thicknesses, locations (base plate/ weld), lengths, and depths. A software that automates the interpretation of these charts for expediting field decision making has also been developed. This process has been successfully used in demanding field conditions.

Please see articles in the Resources section of this website for more information.