Bulging Assessment of Coke Drums

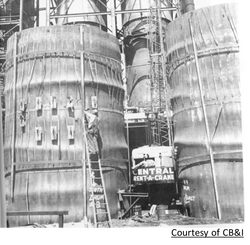

Coke drums are different from other refinery vessels in many ways the most notable of which is the frequency and severity of the failure modes they experience. The shell section experiences severe distortions and cracks unlike any other process vessel. These in-service defects cannot be assessed using industry standards because of the significant complexities associated with defining cyclic thermo-mechanical loads that the shell experiences during operations.

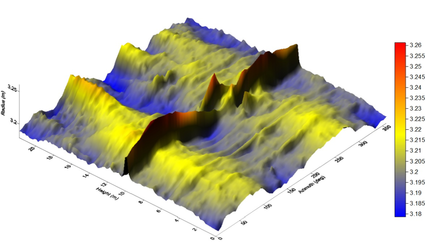

The advent of internal laser scanning has made it possible to accurately measure the magnitude and monitor the growth of bulging in coke drums without interruption to service. However, from an engineering standpoint, laser maps need to be translated into specific guidance on severity and failure potential for each bulge.

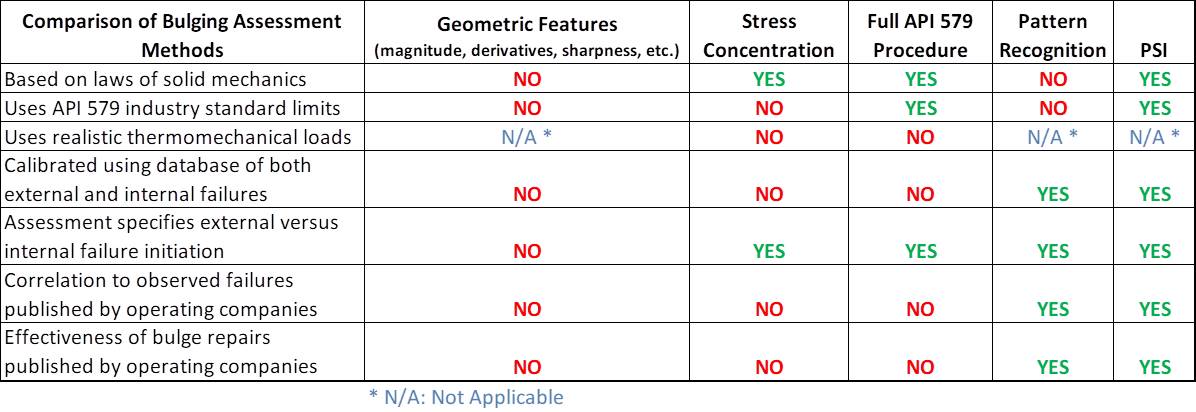

Simplified stress analysis methods, such as the use of stress concentration factors from linear elastic analyses, have been attempted for assessing bulging over the last two decades. However, experience and recent published studies have confirmed that these simplified techniques are inaccurate and can be very misleading. Actually, a similar technique that was used in API RP-579 of 2000 for Level 2 assessment of bulges was found to be misleading and un-conservative and was subsequently removed from the next edition of the document.

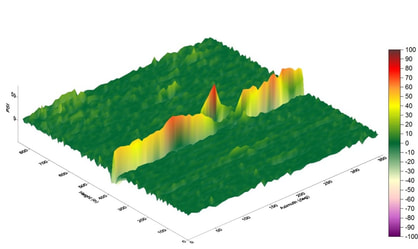

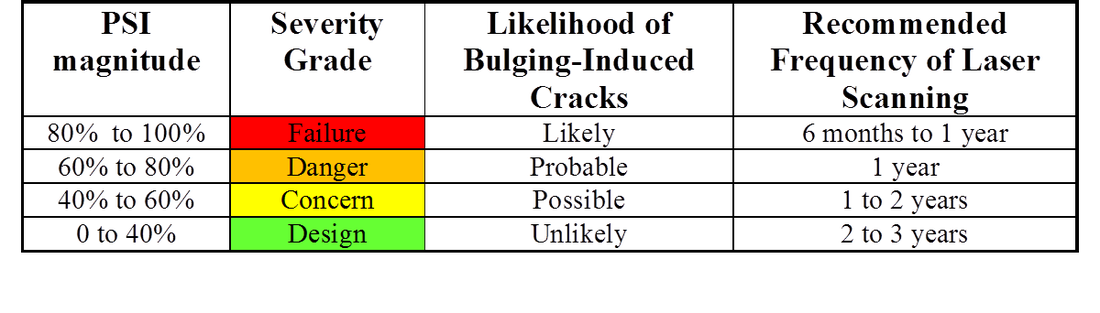

The Plastic Strain Index (PSI)TM is a proprietary HES methodology that was specifically developed for assessing the severity of bulging in coke drums based on observed failure modes. The strain-based technique identifies and ranks the areas that are most susceptible to local failure using strain limits provided by the API 579/ ASME FFS Standard. Safety margin thresholds are used to determine if the severity of bulging at each point on the drum is at the “Design”, “Concern”, “Danger”, or “Failure” level. PSI results are also used to specify whether failure initiation is expected on the inside or outside surface of the drum wall. Overall drum severity is used to recommend inspection needs and the frequency of future of laser scanning.

When more than one scan is analyzed for a given drum, a historical trend can be established. The change in severity for each bulge can be tracked over time and used to prioritize its severity and rate of deterioration.

This state-of-the-art technique helps owners make informed decisions regarding life-cycle management of their drums, helps inspectors plan their work and optimize the allocation of their resources, and helps operators forecast maintenance needs and plan drum repairs in a timely and cost-effective manner.

Please see articles in the Resources section of this website for more information.

The advent of internal laser scanning has made it possible to accurately measure the magnitude and monitor the growth of bulging in coke drums without interruption to service. However, from an engineering standpoint, laser maps need to be translated into specific guidance on severity and failure potential for each bulge.

Simplified stress analysis methods, such as the use of stress concentration factors from linear elastic analyses, have been attempted for assessing bulging over the last two decades. However, experience and recent published studies have confirmed that these simplified techniques are inaccurate and can be very misleading. Actually, a similar technique that was used in API RP-579 of 2000 for Level 2 assessment of bulges was found to be misleading and un-conservative and was subsequently removed from the next edition of the document.

The Plastic Strain Index (PSI)TM is a proprietary HES methodology that was specifically developed for assessing the severity of bulging in coke drums based on observed failure modes. The strain-based technique identifies and ranks the areas that are most susceptible to local failure using strain limits provided by the API 579/ ASME FFS Standard. Safety margin thresholds are used to determine if the severity of bulging at each point on the drum is at the “Design”, “Concern”, “Danger”, or “Failure” level. PSI results are also used to specify whether failure initiation is expected on the inside or outside surface of the drum wall. Overall drum severity is used to recommend inspection needs and the frequency of future of laser scanning.

When more than one scan is analyzed for a given drum, a historical trend can be established. The change in severity for each bulge can be tracked over time and used to prioritize its severity and rate of deterioration.

This state-of-the-art technique helps owners make informed decisions regarding life-cycle management of their drums, helps inspectors plan their work and optimize the allocation of their resources, and helps operators forecast maintenance needs and plan drum repairs in a timely and cost-effective manner.

Please see articles in the Resources section of this website for more information.